Polymer & Co.

nGen ColorFabb

What is nGen colorfabb ?

nGen Colorfabb is a polymer filament made from Eastman Amphora™ AM3300 3D polymer, which is a copolyester. The exact chemical composition of this polymer is proprietary of Eastman and is not provided. However, the copolyesters that are the most used for 3D printing are Poly(ethylene terephthalate) (PET) and Poly(ethylene terephthalate) glycol-modified (PETG).[1]

PET is a thermoplastic polymer including ester groups and aromatic cycles in its linear chain. It’s one of the most commonly used polymer in the world. It can be found in water bottle, clothing fibers, food containers…[2]

PET is synthesised by a two-step reaction polymerization. The first step is the esterification of dimethyl terephthalate (DMT) and ethylene glycol (EG) and the second step is the transesterification of the products obtained.[3]

PETG is a glycol modified PET. Its synthesis takes place the same way as for PET, with the exception that cyclohexanedimethanol is added during the first step of the synthesis. This leads to the final formation of a random copolymer: the PETG.

Regarding the synthesis condition, Chen et al. published in 2015 a synthesis that includes a first step catalysed by organic tin and a second step catalysed by antimony acetate and cobalt acetate.[4]

Due to its easier printing properties as compared to PET, PETG is the most often used in 3D printing. Moreover, PETG is a good compromise between PLA (polylactic acid) and ABS (Acrylonitrile butadiene styrene). It is more flexible and durable as compared to PLA and is easier to print than ABS.[5]

Physico-chemical properties

The printing material

According to Colorfabb[6], nGen is a low-odor and styrene free material suited for 3D printing. This polymer has the advantage that it can be printed within a wide temperature range thanks to its good flow properties. Moreover, it has excellent toughness and temperature resistance properties.

According to the technical data sheet [7] provided by Eastman, the glass transition temperature (Tg) of nGen is 85°C, which is higher than PLA Tg (50°C) and lower than ABS Tg (100°C), the two reference polymers. This Tg is also a bit higher than the one of PET (70°C) and PETG (80°C) which are the most common copolyesters

Processing properties

Eastman gives only few information about the appropriate conditions to print nGen :

-

Processing melt temperature: 210-240°C

-

Heated bed temperature: 60°C

-

Speed: 30 to 100 mm/s

It’s important to note that the processing temperature is higher than the Tg, allowing the polymer to flow properly. On the contrary, the temperature of the bed is lower than Tg in order to allow the polymer to get solid when put in contact with this bed. If on the contrary the temperature was above the Tg, the polymer would remain viscous and wouldn’t bind properly to the bed. Finally, the printing speed corresponds quite well to the average speed (a low one is around 30mm/s and a fast one around 150mm/s)

The advantages of using nGen instead of reference polymers like ABS or PLA come from the fact that nGen was made to avoid the negative aspects of both (warping/odor for ABS, brittleness for PLA). Warping is minimal if you correctly set up your printer settings and there is no odor during the printing. Furthermore, there is no cracking, demonstrating the very good surface finishing as well as inter-layer adhesion of nGen. However, it remains more brittle and more expensive than ABS[8].

Experimental analysis

3D-Printing test

Before starting the characterisation of nGen, it’s important to determine the perfect conditions to print with the 3d printer Makerbot Replicator 2x. To do so, a dog-bone shape was printed with a raft.

Unfortunately, the printing of this shape was not achieved even by varying the printing settings: at each test, on a first step the raft was easily and very well printed but on a second step, the polymer did not attach to the raft resulting in the printer starting to print in the void. Therefore, the shape could not be printed.

In order to solve this issue, several parameters were tested:

-

The standard settings provided by Eastman were first used

-

In a second time, the conditions advised by the “3D printing for beginners” [8] review site were applied (extrusion temperature 230°C, print bed 80°C with a speed of 50mm/s)

-

Finally, the extrusion temperature was modified using different values (220, 230, 240 and 250°C)

Nevertheless, no improvement could be observed with these different conditions.

DSC

For this analysis, a first heating was performed in order to remove all the “history” of the polymer that could influence the final result. The polymer was then cooled down to room temperature with a controlled rate. Finally, it was heated a second time to give the needed information.

In terms of analysis conditions, heating and cooling rates were the same: 10°C per minute and a polymer mass of 7.52mg was used (directly from the polymer coil and without any additional treatment). These analysis conditions are important as they can highly influence the obtained results. For example, if the cooling rate decreases, the measured Tg decreases too.

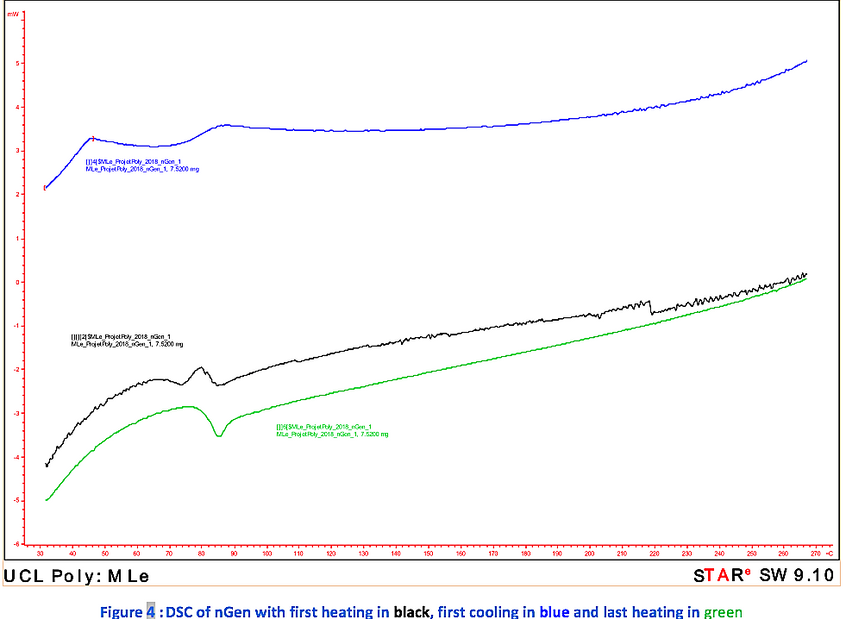

In Figure 4, the black, blue and green lines correspond to the first heating, the cooling and the second heating, respectively. The second heating will allow us to learn more about nGen polymer.

As shown in Figure 4 (green line), there is first a shift in the baseline and further a peak around 80/85°C: this shift corresponds to the glass transition. It can be translated into the heat capacity difference before and after the transition[9]. The observed peak corresponds to the enthalpic relaxation due to the physical ageing of the polymer. The ageing is the process during which the polymer below its Tg will attempt to relax and reach a more stable state. This is achieved by elimination of the excess free volume (the specific volume decreases). As the coefficient of thermal expansion is the derivative of the specific volume and as the specific heat (which is measured here) is proportional to this coefficient, it’ll display a peak in the glass transition. Therefore, this peak should not be interpreted as a real transition, it corresponds to a kinetic artefact, due to the relaxation of the polymer.

In this case, even with the first heat treatment, the polymer stays below its Tg enough time to allow ageing to occur. There is no more transition as no further shift or peak occurs in this line.

In conclusion, nGen is amorphous with a Tg around 80°C and is no more glassy at higher temperatures. Therefore, nGen should not resist to an applied temperature of 120°C.

Rheometry

This analysis allows having a better understanding of the flow behaviour around the processing temperature range of 220-240°C. For the measurement, a small disc was printed, with a 7 mm diameter and a 1 mm thickness.

Regarding the procedure, the analysis was performed by a strain sweep test, ranging from 0 to 30% at 200°C in order to analyse the linear domain. After this first analysis, a frequency sweep test was performed ranging from 0.1 to 100 s-1 at 200°C with a strain of 15%.

The values obtained at low frequency were pretty low and were close to the limit of the rheometer, so the strain was increased to 20% afterward.

The other measurements took place as described below:

-

3 frequency sweep tests at 220°C with a strain of 20%

-

2 frequency sweep tests at 240°C with a strain of 25%

-

2 frequency sweep tests at 260°C with a strain of 30%

In rheometry, it’s important to do repetitions to see if the measurements are reproducible.

5

These results show that:

-

The sample started to turn black from the 3rd test at 220°C and was completely black at 260°C. It started to degrade and to crosslink [10], this affects the measurement by increasing the viscosity. Therefore, the results obtained at 240 and 260°C are biased. As the polymer can degrade at 220°C, it’s important to print fast and during a short time in order to avoid any reticulation.

-

At 200 and 220°C, the storage and loss modulus steadily decrease when the angular frequency decreases. Moreover, G’ is bigger than G’’, we are thus in the liquid domain.[3]

-

The frequency sweep test at 200°C was repeated two times without any change in the obtained values, the sample was stable at this temperature.

-

The two G’ curves at 200 and 220°C, show that the relaxation is faster at 220°C because there is a shift factor between them around 2. In other words, for the same values of angular frequencies, the modulus of G' (220°C) is two times smaller than the modulus of G' (200°C) (this is not clearly visible on the graph due to the fact that the y-axis is in logarithmic scale) showing that the polymer is less viscous at 220°C than at 200°C. Therefore, this polymer is very sensitive to temperature changes. If the temperature increases, the viscosity decreases in a significant way.

In conclusion, the nGen polymer is very sensitive to temperature as much in terms of shift factor as degradation. At high temperature (220-240°C), we are in the liquid domain and thus nGen should flow properly during the printing.

Conclusion

nGen is an amorphous polymer with a glass temperature transition of 80°C. This polymer is very sensitive to temperature: a small difference can generate a big viscosity variation, leading to its degradation. This could explain the fact that this polymer is not easily printed, the recommended processing melt temperature is around 210-240°C while our analyzes have shown that the polymer degrades from 220 ° C

In conclusion, in addition to its difficult printing properties, the nGen polymer doesn’t seem suitable to our project. The main reason is that our working polymer must be able to sustain a temperature of 120°C.

By Pierre

Bibliography

[1] “PETG Filament guide 2018 – explained, compared and reviewed” from the site “All3DP”, url: https://all3dp.com/1/petg-filament-3d-printing/

[2] “16 Different Types of 3D Printing Materials” from the site “3DInsider”, url: http://3dinsider.com/3d-printing-materials/

[3] Lecture “LMAPR2019 - Polymer science and engineering” given by Pr. Jonas, Pr. Demoustier and Pr. Van Ruymbeke at Université Catholique de Louvain (UCL)

[4] Chen, Tingting, Guodong Jiang, Guoyu Li, Zhipeng Wu, and Jun Zhang. “Poly(ethylene Glycol-Co-1,4-Cyclohexanedimethanol Terephthalate) Random Copolymers: Effect of Copolymer Composition and Microstructure on the Thermal Properties and Crystallization Behavior.” RSC Advances 5, no. 74 (2015): 60570–80. https://doi.org/10.1039/C5RA09252C.

[5]« les 25 meilleurs filament 3D » of the site « All3DP », url: https://all3dp.com/fr/1/filament-3d-fil-imprimante-3d-pla-abs/

[6] Site “colorfabb”, url: https://ngen.colorfabb.com/what/

[7] “nGen technical data sheet”, url: http://colorfabb.com/files/AmphoraAM3300-TDS.pdf

[8] « Colorfabb nGen review » from the site “3d printing for beginners “ url: http://3dprintingforbeginners.com/colorfabb-ngen-review/

[9] “Thermal analysis of polymers” in Encyclopaedia of polymer science and technology, Wiley et al., 2005

[10] “Rheological Measurements” in EPSE 2nd ed., Vol. 14, pp. 454–541, by C. K. Schoff, PPG Industries, Inc.; in EPST 3rd ed., Vol. 11, pp. 473–547, by Clifford K. Schoff and Peter Kamarchik Jr., Schoff Associates