Polymer & Co.

Fused depostion modeling

(FDM)

Introduction

The most common Additive Manufacturing (so-called 3D printing) techniques are extrusion-based, they use heat to melt the material that is then forced through a nozzle using rotating rollers, in an assembly called extruder (Figure 1).

The 3D printing extrusion approach is similar to the conventional polymers extrusion, a widely used in process in which the raw material is molten and forced into a die by a system essentially composed of turning screws and heaters arranged along the barrel, however, rather than remain in a fixed horizontal position, the extruder is vertically mounted on a plotting system.

Figure 1 Fused Deposition Modelling

When the material being extruded comes out of the nozzle it must be in a semi-solid state and solidifies as it bonds with the one already extruded, forming a continuous solid structure. The model is scanned layer by layer, once one is completed, it indexes upwards or moves the part being printed downwards and a new layer is started.

Fused Deposition Modeling

Basic principles of FDM

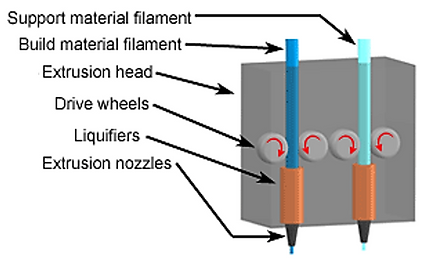

Fused Deposition Modeling (FDM) is the most common extrusion-based Additive Manufacturing technology, it uses a heating chamber to liquefy a polymer that is fed into the system as a filament. This filament is pushed into the chamber by a tractor wheel arrangement which generates the extrusion pressure (Figure 2).

The wide range of materials and the effective mechanical properties of resulting parts obtained from FDM are its major strengths. The models produced using FDM are amongst the strongest made using polymer-based AM.

Figure 2 Extruder

By João

The main disadvantage of FDM comes from the fact that each direction change of the extruder when printing the filament is accompanied by its deceleration followed by acceleration in the new direction of movement, i.e. a speed change. The corresponding material flow rate must then match this change in speed otherwise there will be an accumulation or absence of material deposited in a particular region. As a result, the extruders are designed to operate at slower plotting speed to ensure a fine control of the flow rate, avoiding irregularities in the printed layer (this precision is lost as the printing speed is increased in the setup by the user).

Bibliography

[1] Ian Gibson, David Rosen and Brent Stucker, "Additive Manufacturing Technologies - 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing", 2nd Edition, Springer, 2015

[2] Amit Bandyopadhyay and Susmita Bose, "ADDITIVE MANUFACTURING", CRC Press, 2016

[3] Solid Concepts, "Fused Deposition Modeling (FDM) Technology", Published on 6 Mar 2013, Retrieved from: https://www.youtube.com/watch?v=WHO6G67GJbM