Polymer & Co.

What is FlexiFil ?

Flexifil is a flexible thermoplastic co-polyester (TPC) which is made with some renewable carbon content (43% bio-based oils). [1] The termoplastic compounds can become pliable above a certain temperature and get back a solid behavior when cooled. The flexible part can also be called "elastomer" part, that's why this Flexifil belong to the "thermoplastic elastomer" polymer family.

This polymer is a rubber like high-performance type of 3D printer filament. It offers a unique combination of useful properties as flexibility (with a « flexural memory »), heat resistance, strength, UV resistance and good chemicals resistance [2].

The TPC polymers are semi-crystalline compounds, with an amorphous phase above its glass transition (Tg) temperature and a crystalline one. [3]

Physico-chemical properties

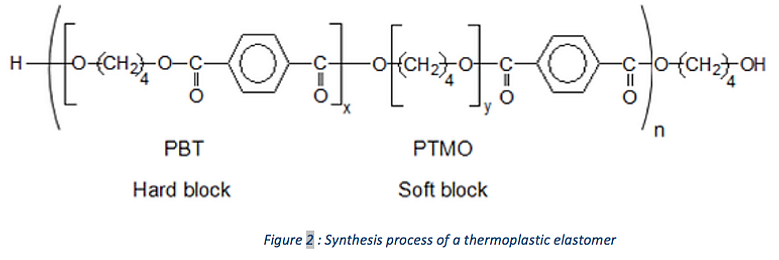

The way to synthesize such polymer is based on polycondensation of the hard block (crystalline) with the soft one (amorphous). For example, with polycondensation of poly(butylene terephthalate) (PBT, hard part) and poly(tetramethyleneoxide) (PTMO, soft part).

So, the thermoplastic property of the polymer is linked to the hard blocks and the flexibl elastomeric property is related to the soft blocks.

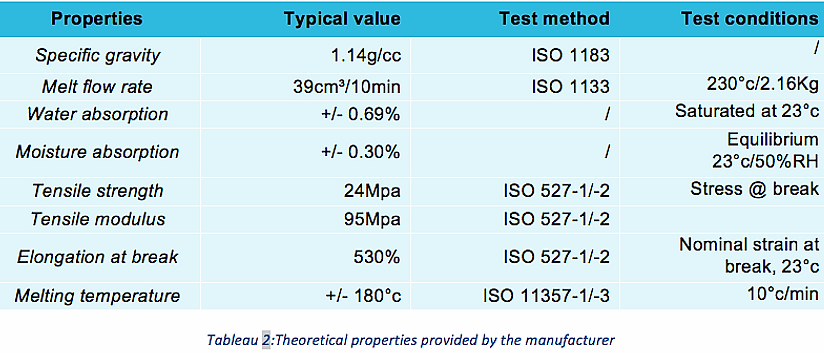

In the following table, one can find the theoretical properties describing the material provided by the manufacturer [4] :

Application field

This kind of polymer is used in a wide range of field, but an interesting one may be in biomedical applications because it shows thermoplastic and flexible properties at the same time.

For example, it can be used to make some artificial vessels or skin, drug encapsulation and in other biotechnologies that need some biocompatible components.

( Das, C. K., Thermoplastic Elastomers - Synthesis and Applications. 2015.)

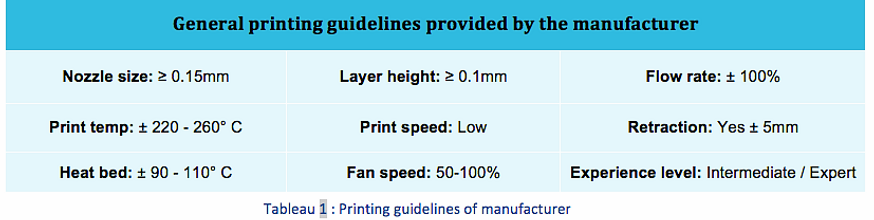

The printing material

One difficulty with FlexiFil encountered during printing is the fact that it can clogg the extruder and we had some difficulties with the feeding of the extruder. [5]

Experimental analysis

FlexiFil

3D-Printing test

By experimentation, we’ve seen that it is preferable to use blue tape for the bed to have a good adherence and a very low print speed (less than 15mm/s) to avoid the warping of this polymer. Furthermore, the use of an extruder head with roller is more convenient for the loading of the filament. And a last thing, it’s preferable to dry the coil before use, in a desiccator (or oven) during a whole night.

Moreover, we have to say that FlexiFil is not so easy to print. We had to do several tests to have a relatively good dogbone.

DSC

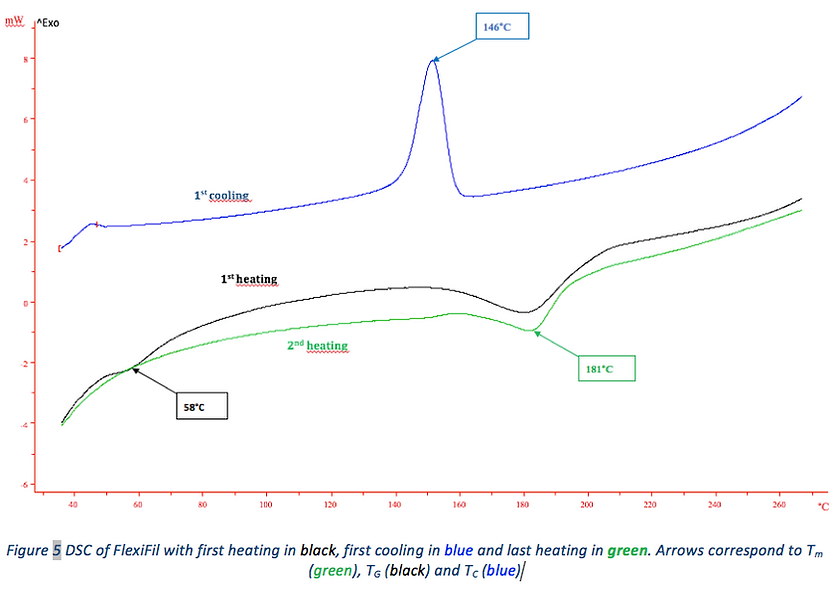

The first heating is supposed to erase the history of the material, and so the second heating is the most important. But in our analysis, we can only observe the Tg transition at 58°C, which is a small endothermic decrease, during this first heating. We make the hypothesis that perhaps, the time of rest of the sample after the cooling wasn’t long enough to clearly see again this glass transition.(link between time of rest and Tg)

Secondly, we see on the two heating curves, an endothermic peak around 181°C, corresponding to the melting temperature. This is in agreement with the semi-crystalline nature of this polymer. This temperature corresponds to the melting of the crystalline part of the sample and above it, the polymer has flow behaviour (because it’s melted, according to the rheological measurements). This is very close to the temperature provided by the supplier which is ~180°C.

A last thing that we can see on this DSC is the temperature at which the molten polymer can recover a semi-crystalline structural arrangement, which is the crystallization temperature (Tc), corresponding to the exothermic peak on the blue line (during the cooling).

4:

Rheometry

We’ve made some rheological measurements to better know the flow properties of the polymer around its melting temperature (~180°C) to ensure the fact that above this temperature, the filament will flow easily during the 3D printing.

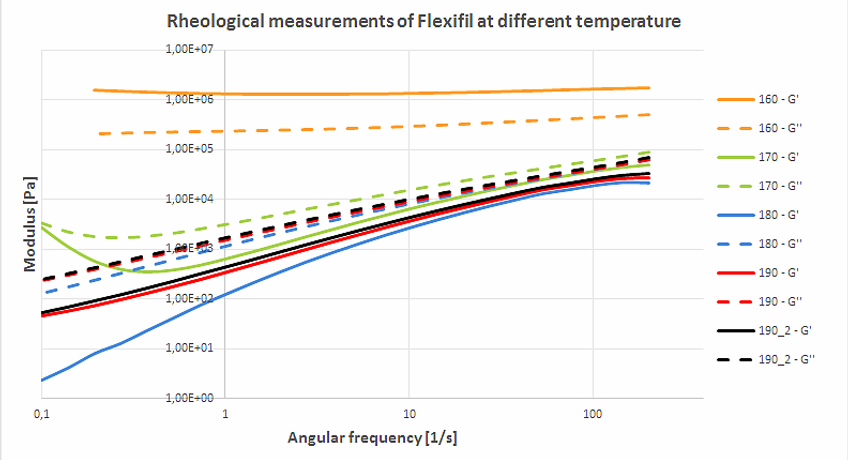

For that we’ve made a strain test from 100% to 0.1% of strain to find the linear viscoelastic region to make further test. We’ve found that the polymer has a linear behaviour in all this strain range, so we’ve fixed the strain at 10% and made a frequency test with an angular frequency from 200 to 0.1/s at different temperature, the results are show in the figure below:

5

We can make some observations about this figure:

First of all, we see that the polymer behaves as a solid (G’>G’’) at all angular frequencies for the temperature fixed at 160°C. This phenomenon is simply due to the fact that at this temperature, we are below the melting point, so it’s a normal behavior.

The 170°C analysis allows us to have an idea of the relaxation of the polymer. We see that the 170-G'' line makes a curve and it’s supposed to reach a plateau at very low angular frequency (lower than 0.1/s, so don't visible on this figure). This plateau corresponds to the part of the polymer that can’t relax, because it’s blocked between two hard blocks. This part of the polymer that can’t relax is called ϕ_trapped and the G’ value of this plateau is linked to this part of polymer trapped.

Also, all the temperatures from 170 to 190°C give a higher G’’ value than G’, which means that the polymer acts as a fluid. But, the interesting thing it’s the fact that the G’ value rises from 170 to 190°C, and also at the second test at 190°C (190_2, the black curve). This is not related to any physical behavior and can be due to some degradation or small measure errors.

Conclusion

We can conclude that flexifil will easily resist at temperature above 120°C and will keep its solid behaviour at least until 170°C , and maybe until 181°C (Tm). But there are some issues with the use of this polymer, mainly the printing!

This polymer doesn’t stick really easily to the print bed, and moreover, due to its flexible property, the printed object will not have really well defined edges.

These issues can be solved by an improvement of the printing process (temperature, print speed, print thickness,…) and can allow us to use this in our final design as a flexible and high resistance polymer !

By Benoît

Bibliography

[1] https://pinshape.com/blog/tips-for-best-results-with-flexible-filament/

[2] https://www.formfutura.com/shop/product/flexifil-black-221?category=163

[3] http://www.polyone.com/products/thermoplastic-elastomers/tpe-knowledge-center/tpe-faqs

[4] https://www.formfutura.com/shop/product/flexifil-black-221?category=163)

[5] https://pinshape.com/blog/tips-for-best-results-with-flexible-filament/